Blog >> slotting and creasing corrugated carton blank

To facilitate adjusting the knife 18, it is shown provided with a laterally or axially disposed ledge or flange 38 which is received in an annular groove 39 provided in the portion 12 of the head 6. The ledge or flange 38 prevents the knife 18 from becoming detached from the head 8, when the clamping ring 16 is partially unscrewed to free the knife 18, whereby it may be circumferentially adjusted in the periphery of the head 6. This is an important feature, as it makes it possible to quickly change the position of the knife 18, with respect to the knife 17 without requiring its removal from the head, and with the assurance that the cutting edge or periphery of the knife 18 will always be accurately disposed with relation to the axis of the head 6.

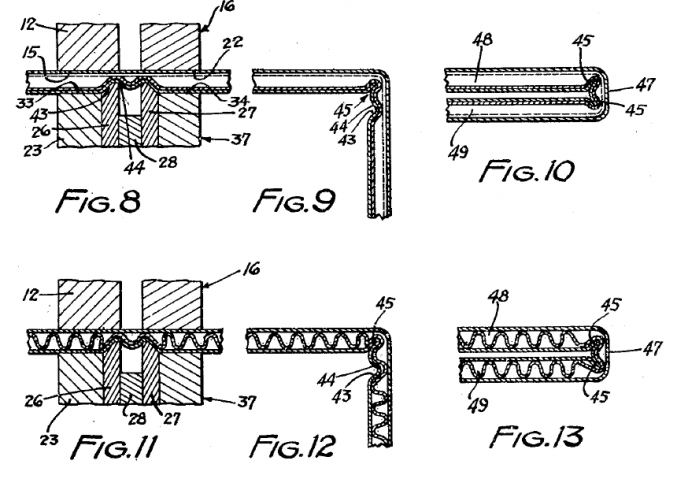

Another important feature of the invention resides in the shape of the peripheral edges of the opposed cutting and creasing members 26 and 27. In the ,manufacture of paper boxes, it is highly desirable that the walls of the finished box are disposed in right-angular relation to one another. Heretofore, some difficulty has been experienced to produce boxes wherein the walls of each box were disposed in right-angular relation to one another, primarily because the conventional method of double line creasing usually allows a slight slackness or looseness at the creases where the blank is folded, which may result in the out side edges of the blank, when folded, not being parallel one with the other resulting in some of the boxes of a given run being rejected for use because of not being uniform in configuration.

To overcome this difficulty I have discovered that by beveling the outwardly facing peripheral corners of the cutting and creasing members 26 and 27, as shown at 41 and 42, respectively, in Figure 6, whereby the combined angle A of said inclined or beveled faces may be less than ninety degrees, that such slackness or looseness at each crease may, be entirely eliminated, with the assurance that each fold in the blank will be in the form of a,true right angle, as shown in Figures 9 and 12, and in the case of double folds, as shown in Figures 10 and 13, the blank walls will be symetrically folded. Thus, when the blank is so creased, all boxes will be substantially uniform in appearance, when set up.

By thus making the combined angle A of the opposed beveled faces 41 and 42 of the cutting and creasing members 26 and 27 somewhat less than ninety degrees, when the panel of a blank

is folded to provide a wall of a box, the inclined wall portions 43 and 44 of each crease, being disposed at less than ninety-degrees with respect to one another, will firmly contact each other, as shown at 45 in Figures 9 and 10, thereby causing the walls to be put under a slight tension as they are bent into right-angular relation. The result is that when all of the panels in a blank have been folded or bent to their collapsible or flat wise positions, all of the walls of the box will be disposed in right angular relation to one another and, in addition, the corners of the box, when the latter is set up, will be relatively non-yieldable as compared to boxes made in accordance with the usual conventional form of creasing. The inwardly facing peripheral corners 46 of the combined cutting and creasing members 26 and 27 have a shear edge surface and provide the cutting edges which co-act with the segmental knives 17 and 18 to slot the paper, as hereinbefore stated.

In double folds such as shown in Figures 10 and 13, the inclined walls 43 and 44 of each crease will firmly contact one another, whereby the outside connecting wall portion 47, shown in Figures

10 and 13, will be under tension and will be disposed at right angles to the parallel wall portions 48 and 49, and the folds or bends between the wall portions 47, 48 and 49 will be such that the paper is under a slight tension at the corners of each bend, thereby causing all bends or folds to be substantially right-angular in cross-section.

Each combined cutting and creasing member 26 and 27 is preferably made in two halves, as indicated at 51 in Figures 4 and 5, in order that they may be quickly removed for sharpening. The parts or halves of each such member are retained against relative outward and rotary movements upon the member 23 by suitable dowel pins 52, the clamping ring or nut Ii serving to securely fix them in the head, whereby they become, in effect, an integral part of the head, as will readily be understood by reference to Figures 2 and 3. To remove the member 26 and 27 from their supporting head. 1, it is only necessary to partially unscrew the clamping ring or nut 16 and remove the dowel pins 52, after which the two halves of each member 26 and 27 may readily be removed from

the head without removing the head from the shaft 9.

The segmental knife sections 17 and 18 may be similarly removed from their supporting head 6 by partially unscrewing the clamping ring or nut 16 sufficiently to permit the lateral flange or ledge 38 of the knife 18 to be withdrawn radially from its supporting recess, as will be understood by reference to Figure 2. The knife 17 may readily be removed, when the clamping nut 16 is loose, by withdrawing the dowel 21.

SinoCorrugated Exhibiton is the biggest and most important exhibiton for corrugated carton flexo pri...

In 1989s, China begin reform and opening, there exist mostly state-owned factories before that. Aft...

Corrugated Box Making Machine and ProcessAs used herein and as well understood in the industry, corr...

What are the types of corrugated boxes which are used in industries?The factors that are considered ...

Corrugated boxes are made from corrugated paper which is glued to the flat facing of a flat paper ma...