Technology >> Rotary die cutting machine for corrugated carton and box

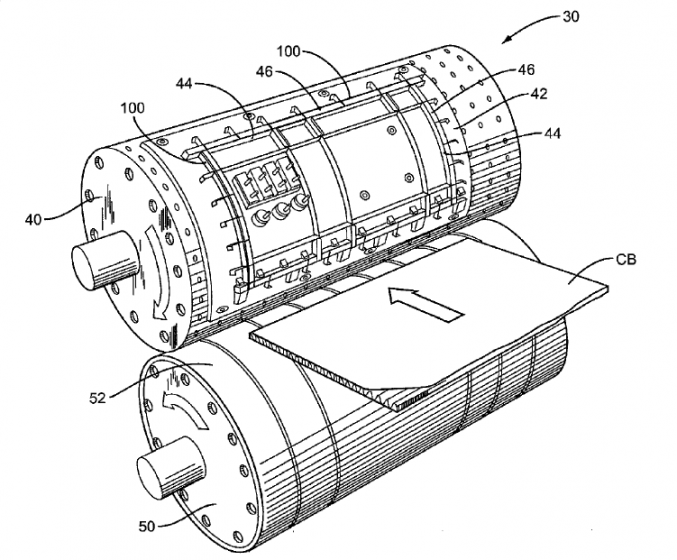

30.rotary die cutting machine 40.die board cylinder 42.die board 44. Trim cutting blades 46.trim stripper 50.anvil cylinder 52.coating 100.retainer

1. The function of rotary die cutting machine for corrugated carton and box.

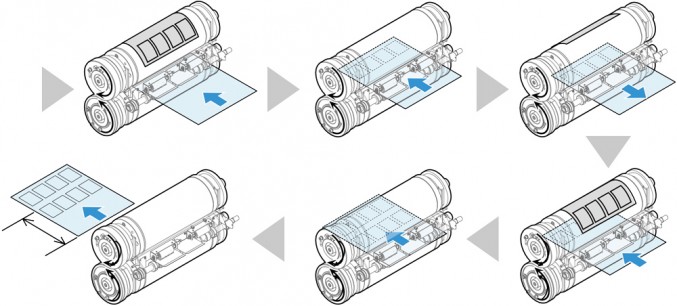

The rotary die cutting machine is designed to receive sheets of corrugated board and to trim the sheets of corrugated board to yield a product board. Further the rotary die cutting machine is designed to cut, score and in some cases remove scrap from ares of product board. In the end condition the corrugated board such that when the corrugated board exits the rotary die cutting machine, the product board can be easily manipulated into a box configuration.

2. The introduction of die board cylinder

The die board cylinder is designed to receive and hold a die board, including the die board is disposed with respect to the anvil cylinder such that a nip is defined there between. Ascorrugated are fed through the nip, corrugated board is engaged by the die board which trims, cuts and scores the corrugated board.Die board is typically constructed of laminated plywood, includes a combination of cutting blades, creasing rules, resilient scrap strippers, resilient product ejectors and the like.

3. The function of anvil cylinder

The anvil cylinder is typically surrounded or sheathed with a surface layer or coating of relatively compliant material such as urethane, which provides a backing surface against which a cut can be made without damaging various components carried by the die board. As such, anvil cylinder rotates in a manner that is generally synchronous with the adjacent die board cylinder during normal operations.

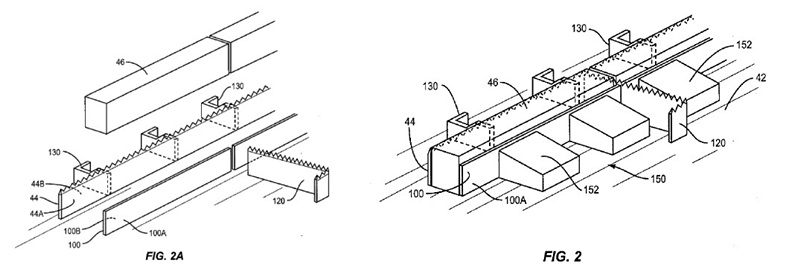

4. Trim cutting blades for rotary die cutting machine

More particularly, the die board includes a series of trim cutting blades which are securely mounted in the die board such that the cutting tips of the blades protrude and extend generally outwardly and away from the surface of the die board cylinder. Trim cutting blades extend generally around an area of the die board. For example, the rim cutting blades include one or more leading trim cutting blades such as shown in FIGS. 2 and 12A.

The trim cutting blades trim small trim pieces from the outside edge of the corrugated board. This leaves a product board or a product portion of the corrugated board. Die board and the elements thereon operate in the product portion to cut and score and form the product board into a corrugated panel that can be shaped and formed into a corrugated box or container.

The term “trim cutting blade” or “trim blade” is specifically defined as a blade that trims the corrugated board and cuts a piece of trim from around edge portions of the corrugated board to leave the finished die cut product. The term “trim cutting blade” or “trim blade” specifically excludes any scrap cutting blades located within the area defined by the overall length and overall width of the finished die cut product.

5.Trim stripper on die cutting blades

Trim stripper is disposed adjacent trim cutting blades. In some cases, the trim strippers are referred to as elastomer trim transfer devices. The trim strippers are positioned adjacent the outboard side of the trim cutting blades. They function to engage the cut trim pieces cut from the corrugated board by the trim cutting blades and direct the cut trim pieces away from the trim cutting blades and away from the product portion of the corrugated board Trim strippers can assume various shapes. In the embodiment illustrated herein, the trim strippers are generally elongated and are generally rectangular or square in cross section. The trim strippers are resilient and compressible and are typically manufactured from a resilient material such as a urethane having a durometer of 85 on a Shore 00 scale and having a density of approximately 45g/cm3 .

6.The working process of rotary die cutting

In conventional rotary cutting dies there is a tendency for the trim strippers to bow. That is,as the die board rotates and the trim strippers engage cut trim as well as the anvil, the trim strippers tend to bow, leaving a gap between the trim strippers and the outboard side of the trim cutting blades. This results in the inboard side of the trim stripper moving away from the adjacent trim cutting blade.Often, this leaves the gap between the trim cutting blade and the trim stripper. Over a period of time, small cut pieces of trim tend to Wedge themselves between the trim cutting blade and the adjacent trim stripper. This over time causes substantial forces to be applied against the blade and ultimately the die board, often resulting in damage to the die board.

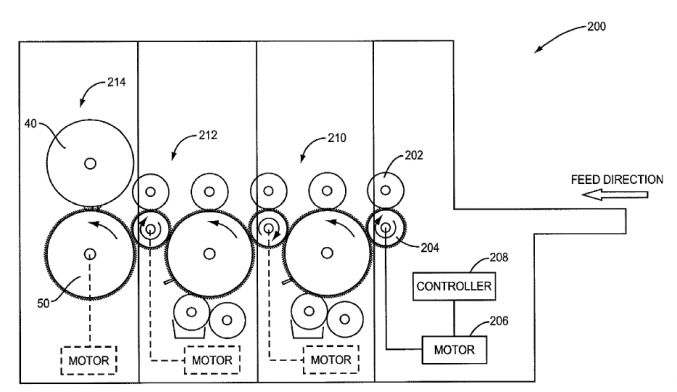

202.204 rollers 210.first print station 212.second print station 214.die cutting station

Flexo printing and die cutting machine is used for printing and die cutting corrugated board, includes three basic operating stations. Located downstream from the second print station is a die cutting station. Die cutting station includes the rotary die cutting : rotary die cylinder, anvil cylinder and die board. Upstream from the first print station is a pair of rollers. Roller 204 is driven by a motor that’s controlled through a controller. Roller 204 has a gear associated therewith that’s effective to drive the components of the first print station, The first print station includes a gear network that is operative to drive the second print station which likewise has a gear network that is operative to drive the die cutting station.

The work process of flexo printing and die cutting machine

The corrugated board is fed into the nip between rollers and continues generally horizontally through the die cutting station. In the process, printing plates carried by the print rollers of the first and second print stations are operative to print indicia, designs etc,on the passing corrugated board. Once the corrugated board clears the second print station, it enters the die cutting station and the die board and the elements thereon trim the corrugated board and further cut and act on the remaining product board.