Products >> Corrugated Box Making Machine Core Parts >> Automatic feed section of flexo folder-guler

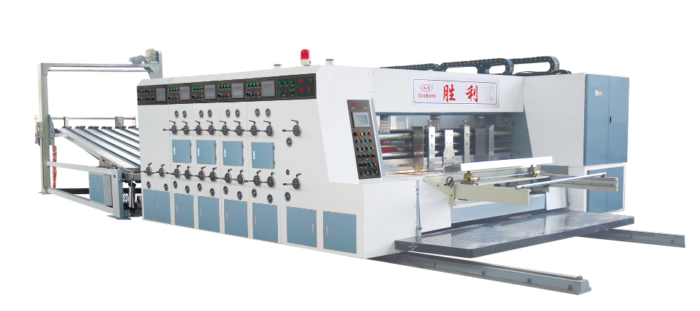

Automatic feeding section of corrugated box making machine

The beginning of the box conversion process happens in the feed section where blanks enter the machine. This section is responsible for taking each individual blank, already scored across the flutes, into the flexo folder-gluer. As each blank enters the machine, it must be flat and aligned correctly. If the blank is not aligned squarely with the machine, problems arise in the feed section or later in the process. Most times these problems are a result of human operation. However, problems that occur because of machine error, such as one side of the board entering the machine before the other, can also cause lost productivity.

Two different feeding methods exist and each is used for a different reason. Blanks are fed into the machine in one of two ways – from the top of the stack or from the bottom of the stack. Bottom feeding, also known as top stacking, is the most economical way of feeding. This process takes each blank from the bottom of the stack which allows the operator to easily place blanks on the top of the stack. Although this method is less time consuming and less complicated for the operator, if too many blanks are stacked in a pile, friction on the bottom blank becomes too great and the bottom blank cannot be moved into the machine. Top feeding, also known as understacking, is a more recent innovation that is mostly used for large blanks. Understacking usually requires an operator to manually move the blanks into the machine resulting in increased costs.

Two variations for feeding the blanks into the machine exist, both with different downfalls. Several variants of both pushing and pulling operations exist. This part of the operation must be carefully overseen to ensure efficiency and quality. If pushed or pulled to harshly, the board will be damaged. If the process is too gentle, the blank may not enter the machine squarely and cause problems as the blank continues to move into the printing section and through the rest of the machine.

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...