Blog >> Automatic Printing Slotting Creasing Die Cutting Folding Gluing Machine

Automatic Printing Slotting Creasing Die Cutting Folding Gluing Machine

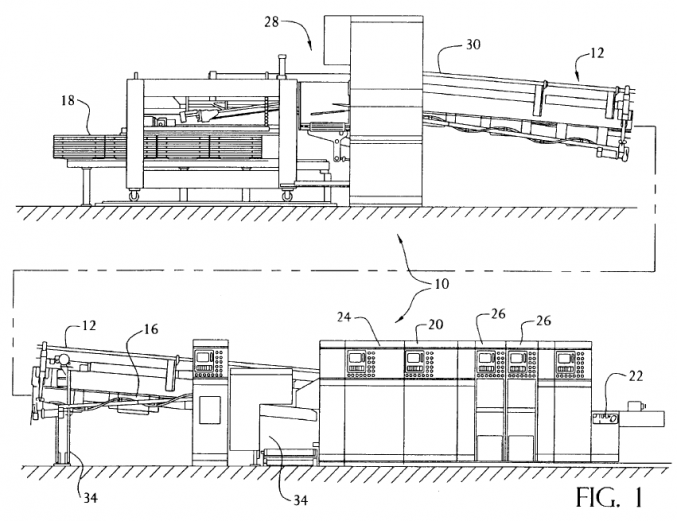

10.flexo fold 12. folder-gluer (folding gluing machine) 16.paperboard blanks 18.collapsed box 20.creasing slotting unit 22.feeding unit 24.die cutter 26.printing unit 28.counter ejector 30.input shaft 34.movable legs

FIG. 1 is a side view of the apparatus in the context of a flexo folder gluer machine;

Referring to the drawing in detail, where like numerals indicate like elements, there is illustrated a flexo folder gluer device in accordance with the present machine designed generally as 10. Referring to FIG. 1,a folder-gluer 12, is grouped as one in a series of machines operating in timed relationship in the flexo-folder gluer 10 to convert a plurality of paperboard blanks 16, one-by-one, into a plurality of collapsed boxes 18.

The folder-gluer 12 receives its feed from a rotary die cutter 24 which receives its feed indirectly from a feeding unit 22. Between the feed unit 22 and the rotary die-cutting unit 24, in the embodiment shown in FIG. 1, is a creasing-slotting unit 20 and a plurality of printing units 26. In the embodiment shown, a counter-ejector 28 is located after the folder- gluer 12. The flexo-folder gluer 10 is modular and allows units which are not required in a particular installation to be removed.

Typically, the flexo folder gluer 10 is operated by a single drive or a split drive system having a pair of drive motors (not shown). Typically, one of the drive motors is located in the rotary die-cutter unit 24 and the second is located in the folder-gluer 12. The first drive motor drives the feeding unit 22, the printing units 26, and the creasing-slotting unit 20.

The second drive motor drives the folder-gluer 12, as explained below, and the counter-ejector 28. The second drive motor transmits power to the counter- ejector 28 via an input shaft 30. The speed of the input shaft 30 and the entire operating sequence of the machines are controlled with the drive motors such that the entire series of machines is operated synchronously. As discussed in further detail below, certain elements are controlled independently of the motors.

SinoCorrugated Exhibiton is the biggest and most important exhibiton for corrugated carton flexo pri...

In 1989s, China begin reform and opening, there exist mostly state-owned factories before that. Aft...

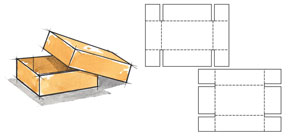

Corrugated Box Making Machine and ProcessAs used herein and as well understood in the industry, corr...

What are the types of corrugated boxes which are used in industries?The factors that are considered ...

Corrugated boxes are made from corrugated paper which is glued to the flat facing of a flat paper ma...