Products >> Corrugated Cardboard Porduction Line >> Automatic Reel Roll Stand and Splicer

Automatic Reel Roll Stand and Splicer

Automatic Reel Roll Stand and Splicer is designed for High Production and Straight Cutting of Sheet or Two ply corrugated Board without damaging flutes and linear paper. While corrugator machine is in operation, it is easy to adjust the sheets with the help of a wheel. For stacking sheets a delivery conveyor is provided to carry the cut sheets, This machine can also be synchronised directly with corrugation machine.

Automatic Splicing is a process in which web materials are automatically joined together through a cut and tape process in order to streamline production capabilities. Butler Automatic Splicers are configured vertically or horizontally, there is one running web roll and one in a stand by position. When the running roll is expiring the machine fires a splice, joining the end of the expiring web roll to the leading edge of the new roll. An accumulator holding web material storage is used to keep production running while the splice is taking place. When the splice is finished the accumulator is re-filled and the expired roll can be changed while the new roll is running, eliminating any stoppage in production. Due to low inertia and ultra sensitive tension controls and drive motors, they are able to handle very thin films and materials liable to stretching.

Key features include: Rotating turret with ‘Phantom axis’ and thus compact design Shafted design with pneumatic air shafts and flip-back type safety chucks Shaftless design with arms that move in and out to accommodate web width without the need for spacers and optional lift tables Unwinds capable of splicing in under-wind or over-wind mode with splice knives and operating cylinders mounted within turret assembly Tension control with dancer roll feedback upon regenerative drives Minimum unglued tail at splice Non contact sensing of surface speed and splice timing mark Rewinds with bump roll switching to lay on roll mode for perfectly wound reels.

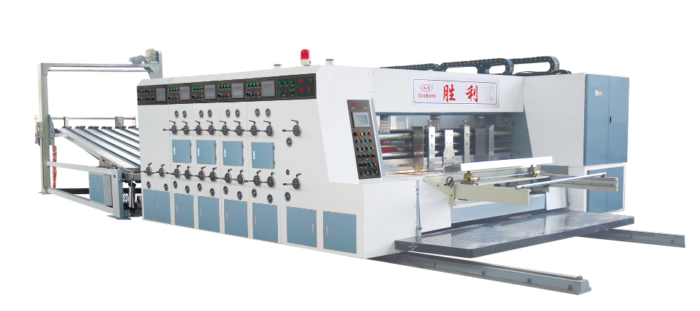

Hebei Shengli Carton Equipment Manufacturing Co.,Ltd is one of the largest Corrugated Carton & Box Making Converting Printing Machines Equipments manufacturers in China, supply high quality machines and good service for corrugated box plants wordwidely. We are specialized at corrugated box carton & cardboard machines . Corrugated sheet making machine, corrugated sheet cutter, boardcard slitter, flexo printing press, box folder & gluer, corrugated cardboard die-cutting machines. Anything you have interested, please contact me : corrugatedboxmachine@hotmail.com

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...