Products >> Corrugated Cardboard Porduction Line >> Double Backer for Corrugator Machine

Double Backer for Corrugator Machine

The double face board is to be made, the single face produced by the operations just described must be glued to another liner. The back or bottom liner is unwound from a similar flying splice type unwind also found under the bridge. The bottom liner may also be sprayed with steam or heated to increase the similarity between it and the rest of the assembly, to reduce the tendency to curl,as can be seen in figure 9.2

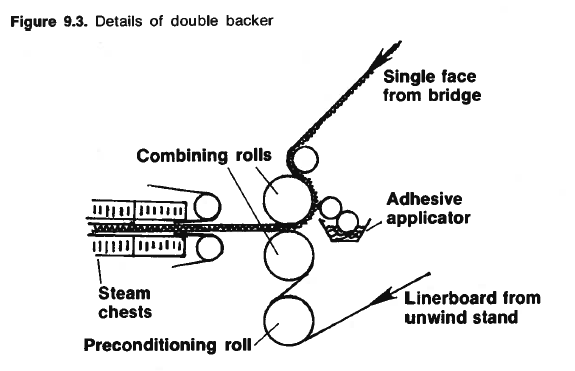

Figure 9.3 Detail of double backer

The single face is brought from the bridge and adhesive applied to the tops of the exposed flutes. The pressure used in this nip must be controlled to ensure that flutes are bot crushed, but that all flutes receive enough adhesive to bond the board together. The top of the single face may also be sprayed with steam to help equalize the board moisture content and prevent curling.

Shortly after the adhesive is applied to the single face, the back liner is brought into contact with it and the assembly is fed between two continuous belts into the steam chest. The adhesive used for this operation is similar to the first, but need bot be capable of developing the quick or green tack, since these layers are held together under pressure and heat to dry and cure both glue lines. The pressure is sufficient to hold the layers together, but must both be so great as to crush the flutes.

To make double wall board, another single facer,bridge and double backer gluing station would have to be installed on the machine. In fact, most corrugating machines are built with two sets of corrugating rolls and prevision for making double wall board. The addition of the second set of corrugating rolls has value other than just the manufacture of double wall. The two sets of rolls are generally in two different flute sizes, perhaps an A flute and a B flute. Both flutes combined in one double wall give it puncture and edgewise-compression resistance. The use of one size of flute at a time allows the manufacture of either of two different types of double face.

Unique structural design has advanced innovation and practicality.Based on advanced technology...

Printer characteristicsThe QYKM series of high speed flexo ink corrugated cardboard printing, slotti...

YKW1270 High Definition Flexo Printer with Die CutterYKW High Speed Corrugated Carton Flexo Printin...

GYK910/1270 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo pri...

GYK1700 Flexo Printing Machine with Slotter Die CutterGYW High speed corrugated carton flexo printin...

GYK-A Flexo Printing Machine with Slotter Die Cutter-140 Pics/minGYK-A is improved model of YFQ flex...